%20electrical%20wire%20fo.jpg)

regulares EPDM STANDARD PRODUCTS: Regular, compact EPDM formsompacta

Main characteristics

-

Standard hardness is 70º shore A but we can also manufacture between 40º and 85º shore A and spongy or cellular EPDM with or without adhesive.

-

Black is the usual color, but we produce white pieces too.

-

We manufacture some specific formula in White color, meeting the FDA American ruling.

General properties

Characterized by high flexibility at low temperatures, which means it can be adequate for outdoor applications. Excellent resistance to air, heat and ozone, which translates into a high lifespan. Excellent resistance to vapor. Resists temperatures between -45ºC and +120ºC.

Mechanical properties

High friction coefficient, also in low temperatures. Less resistant to abrasion that the NBR rubber.

Electric properties

Good electric properties.

Chemical properties

EPDM is unsatisfactory for use in areas where the next chemicals are used or stored: gasoline, kerosene, oils, halogenated solvents, concentrated acids, aliphatic or aromatic hydrocarbons.

When these chemicals make contact with EPDM, can start the decomposition of this material, and even its melting.

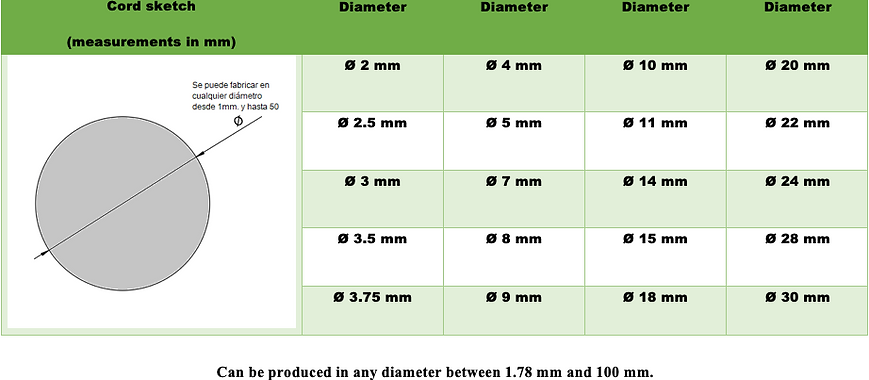

Most standardized EPDM cords and derivate toric joints

The fabrication standard of cords or rounded EPDM is an extruded profile of calibrated circular section, manufactured in diverse dimensions. JV Group extrudes from 1.7 mm and up to 100 mm, in different roll lengths (25 m, 50 m and 100 m). Depending on the client’s needs, the roll format can vary, and we even manufacture other intermediate diameter measures (2.5, 3.5, etc.) and cut pieces starting from 1mm of length. The due date, although variable, is a maximum of 1 week in roll format, 2 weeks if cut.

Most common diameters are:

Arcade, Industrias J.V. and Elastómeros J.V. produces, starting from a toric profile cut in the desired measure, toric joints whose two endings are glued using cyanoacrylate or Loctite®. We recommend the use of glued toric joints only in static applications. For dynamic applications, we recommend vulcanized joints. These toric joints don’t have development limit and work really good in tightness applications without the need to invest in an expensive mold for its manufacturing, working in valve sealing, bombs, doors, O-ring type seals of big size, stopcocks, tanks, transformers, self-sealing valves, among other applications.

For the toric joints, it is essential that the placement where the joint will act is accurately calculated in shape and dimensions, since the correct functioning of the joints will depend on that.

The dimensions of the toric joint are given by its interior diameter (d1) and its thickness, or the diameter of the extruded cord (d2).

To choose the correct toric joint we have to be aware of the resistance to the fluid to which it has to keep tight against (joint swelling can happen, but never compression), resistance to work temperatures, resistance to wear and deformation and selection of the adequate hardness depending on the pressure it will need to resist. In case of any doubt, please contact with our technical department.

Most standardized diameters of EPDM tubes, its flat washers and derivate tubular sleeves

Arcade, Industrias J.V., S.A. and Elastómeros J.V., S.A. produces compact tubing and hoses from an interior diameter of 1 mm and up to an exterior diameter of 180 mm, with wall thicknesses starting from 0.25 mm, provided in different roll lengths (25 m, 50 m y 100 m) depending on the client’s needs. We also manufacture, if needed, other intermediate diametric measures (2.5, 3.25, etc.).

Through this tubing, JV produces EPDM washers or flat joints, cut pieces, flexible hoses or tubular sleeves starting from 1 mm of length. Washers are frequently used for proper sealing of the unions of closing elements where tightness is important, and generically in any hydraulic or pneumatic element to avoid fluid leaks because of mechanization malfunctioning in closing areas, even having internal pressures, for example in engines and compressors. This saves a lot of money because it allows the mechanization not to be totally perfect in coupling.

Another common product made from tubing is the inflatable joint. It is widely used as a solution for coupling moving parts, that can be connected or disconnected through the inflating or deflating of the joint. One of its more extended uses is in the area of acoustic isolation.

Also, JV manufactures tubular sleeves with this tubing. They are generally used as a technical solution for fluid transfer, in refrigerating systems, admission, heating and engines. The due date for a EPDM hose (given in meters) is 2 weeks, 3 if cut or manipulated.

The most common diameters in tube sleeves are:

Most standardized EPDM squares and squared joints

Arcade, Industrias J.V., S.A. y Elastómeros J.V., S.A. manufactures compact, squared EPDM cords (extruded profile of calibrated square) both in solid and with perforations, and also with holes between 2 mm x 2 mm up to 80 mm x 80 mm. They are profiles generally used for the realization of squared joints. The joints of square profile are used for static applications such as flanges, covers, pistons, stems, alternative movements, for tightness of axis and rotating joints in movement and specially where toric joints have torsion risks. We have tools of all measures between 2mm x 2 mm and 80 x 80 with possibility to create perforations and internal holes.

The most common measurements are:

Most standardized EPDM rectangles and rectangular joints

Arcade, Industrias J.V., S.A. y Elastómeros J.V., S.A. manufactures compact, rectangular profiling and strips or bands (extruded profiles of calibrated rectangular section) both solid and with perforations or holes between 0.5 mm up to 80 mm.

The most requested bands are:

For EPDM rectangular profiles, the JV Group has moving lines that allow the manufacturing of any rectangle. The most common application of this profiles is tightness joints and packaging.

The most used rectangles are:

All this range of EPDM articles: cords, tubes and hoses, squares, rectangles, as well as flat joints, round joints or washers, can be manufactured in all types of hardness and bases (compact or cellular) in black and white and meeting regulations and/or special physical and mechanical characteristics. Please consult with our technical department different possibilities such as welded joints, glued joints, inflatable joints starting from a tube or cord (with or without reinforcement) and adhesive on one face or two faces.

Pol. Ind. Can Salvatella, C/. Cabanyes, 33-37. 08210 Barberà del Vallés (Barcelona). Tel. 93 719 21 00 Correo: comercial@elastomerosjv.com